Reciclagem

A NewTechWood desvia mais de 30.000 toneladas de resíduos de plástico dos aterros e da incineração todos os anos. Isto reduz a quantidade de plástico que, de outra forma, contribuiria para a poluição e a degradação ambiental.

Conservação

Os nossos produtos constituem uma alternativa sustentável à madeira tradicional. A madeira é derivada de materiais de resíduos de madeira, tais como serradura, aparas de madeira e cortes. Estas fibras de madeira são provenientes de práticas florestais sustentáveis como subprodutos de outros processos de fabrico de madeira. Ao utilizar estes materiais residuais, a NewTechWood ajuda a minimizar a pressão sobre as florestas naturais e reduz a necessidade de abate de árvores.

A NewTechWood utiliza madeira 100% reciclada, evitando o abate de cerca de 900.000 mil árvores.

Menor impacto ambiental

A NewTechWood requer menos energia e emite menos gases com efeito de estufa em comparação com os produtos de madeira tradicionais. Este menor impacto ambiental ajuda a mitigar as alterações climáticas e reduz a pegada ecológica global associada às actividades de fabrico e construção.

Lower Environmental Impact

NewTechWood’s requires less energy and emits fewer greenhouse gases compared to traditional wood products. This lower environmental impact helps to mitigate climate change and reduces the overall ecological footprint associated with manufacturing and construction activities.

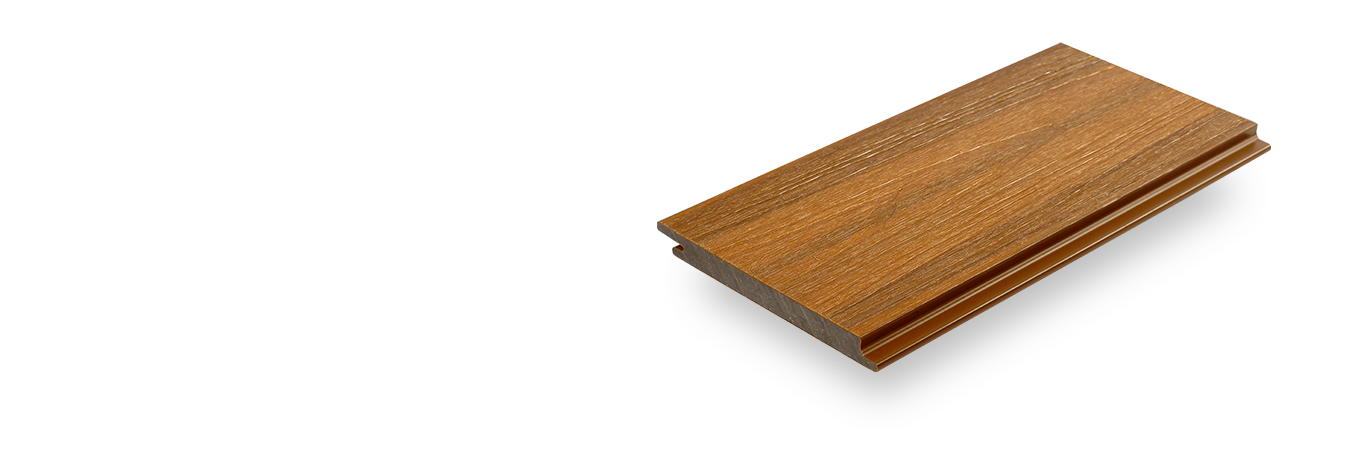

NewTechWood reacted to the growing public concern for environmental sustainability by providing consumers with innovative building materials from a sustainable process. NewTechWood’s foundation was built upon the following green principles and values:

- • Products are made from 95% recycled materials, including plastic bottles and reclaimed wood fibers.

- • Yearly third party audits to comply with environmental, health, and safety guidelines and regulations.

- • Reducing our carbon footprint through waste reduction, energy conservation, and utilizing an optimum process.

We were “Green” before “Green” was fashionable. Our parent company has been recycling plastic materials for almost 30 years. Every month we save over 12,000,000 pounds of plastic from being buried in our landfills forever. Since we control the entire recycling process, including the proper washing, sorting and screening for impurities, we know exactly what material is going into our products. Total vertical integration of our manufacturing process allows us total control, for consistent quality, and color. It also allows us to manage our material costs for stable pricing, and dependable product availability.

UltraShield® offers 25 years limited warranty that includes the industries first warranty to include labor costs.